Conveyor Belts

Steel Cord Conveyor Belt

Designed for heavy-duty industrial applications, steel cord conveyor belts deliver exceptional tensile strength, low elongation, and long service life. Ideal for mining, cement, power plants, and bulk material handling over long distances.

Conveyor Belts

EP Conveyor Belt

EP conveyor belts offer excellent flexibility, abrasion resistance, and load-bearing capacity. Widely used in stone crushing plants, ports, cement factories, and coal handling systems for medium to heavy-duty conveying operations.

Conveyor Belts

Chevron Conveyor Belt

Chevron conveyor belts feature a raised pattern for superior grip on steep or inclined surfaces. Perfect for transporting loose materials in brick plants, grain mills, cement industries, and applications requiring efficient incline conveying.

Conveyor Belts

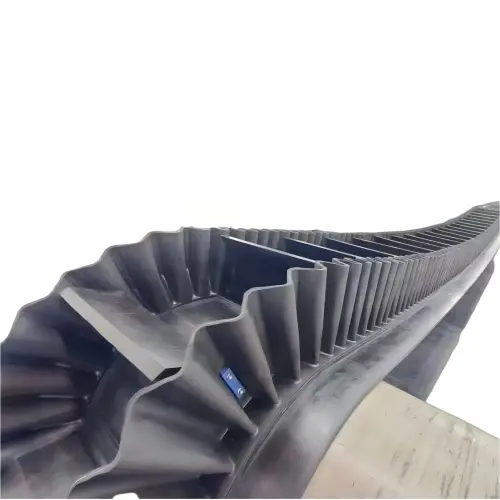

Sidewall Conveyor Belt

Sidewall conveyor belts are designed for steep-angle and vertical conveying with minimal material spillage. Equipped with corrugated sidewalls and cleats, they are widely used in cement plants, steel mills, and bulk material handling applications where space optimization is critical.

Conveyor Belts

Fire Resistant Conveyor Belt

Fire resistant conveyor belts provide enhanced safety in high-risk environments such as underground mines, tunnels, and power plants. Manufactured with flame-retardant compounds, they help prevent ignition and slow fire spread while ensuring reliable material transport.

Lifting Hardware

Wire Ropes

Wire ropes are essential for lifting, pulling, and securing heavy loads across industrial and construction applications. Known for their high tensile strength and flexibility, they are widely used in cranes, hoists, and winches. Available in galvanized and stainless steel options, including popular constructions such as 6×19 and 6×37.

Lifting Hardware

Slings

Slings are used to connect lifting equipment to loads, ensuring safe and controlled lifting operations. We offer wire rope slings for durability, chain slings for high-temperature and heavy-duty applications, and synthetic slings for lightweight and delicate loads. Selecting the correct sling depends on load weight, lifting method, and operating conditions, making them a critical component in rigging systems.

Lifting Hardware

Rigging Hooks

Rigging hooks provide secure attachment points between slings, chains, and loads. Available in eye hooks, clevis hooks, and self-locking hooks, they are designed to meet strict safety and load-bearing standards. Proper latch mechanisms and rated capacities help prevent accidental disengagement, making rigging hooks vital for safe lifting and material handling operations.

Lifting Hardware

Shackles

Shackles act as strong connecting links in lifting and rigging assemblies. Commonly used to join slings, wire ropes, and lifting devices, they are available in anchor, chain, and screw-pin types. Manufactured from high-strength steel, shackles are designed to meet specified Working Load Limits (WLL) and provide dependable performance in heavy-duty lifting applications.

Material Handling Units

Idlers (Front Idler)

Front idlers guide the track chain and maintain proper alignment during machine operation. Designed to absorb shock and support track tension, idlers help reduce uneven wear and ensure smoother performance in demanding environments.

Material Handling Units

Rollers (Bottom / Lower Rollers)

Bottom rollers support the machine’s weight and guide the track along the ground. Built for high load-bearing capacity and resistance to wear, they ensure stable movement and consistent undercarriage performance even in rough operating conditions.

Material Handling Units

Top Rollers (Carrier Rollers)

Top rollers support the upper section of the track chain, preventing sagging and maintaining correct track alignment. They play a key role in reducing vibration and wear, contributing to improved machine efficiency and extended undercarriage life.

Material Handling Units

Track Tensioners (Springs / Cylinders)

Track tensioners maintain optimal track tension, preventing derailment and excessive wear. Using spring or hydraulic cylinder systems, they absorb impact forces and adapt to changing ground conditions, ensuring reliable and safe equipment operation.

Material Handling Units

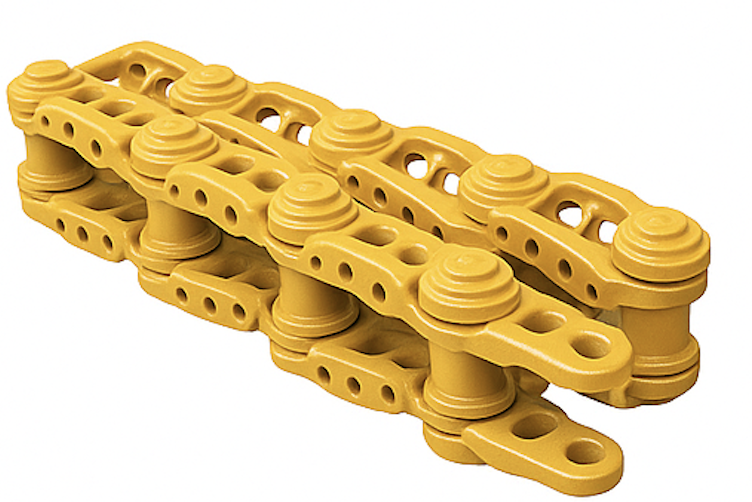

Track Chains / Links

Track chains form the core of undercarriage systems, providing strength and stability for tracked machinery. Manufactured from high-grade steel, they are designed to withstand heavy loads, harsh terrain, and continuous operation while ensuring smooth movement and long service life.

Material Handling Units

Track Shoes / Pads

Track shoes offer ground contact and traction for tracked equipment. Available in various widths and designs, they help improve machine stability, reduce ground damage, and enhance performance across different working conditions, including soft soil, rocky surfaces, and paved areas.

Material Handling Units

Sprockets

Sprockets transmit power from the drive system to the track chain, ensuring efficient machine movement. Precision-engineered for durability and proper tooth engagement, sprockets minimize wear and maximize the lifespan of the undercarriage components.